Hybrid heat: One way to reduce costs

February 23, 2018 | By Ian McTeer

The point of a hybrid system is to reduce operating costs while maintaining year-round comfort conditions, whatever the weather.

I found this definition of a hybrid heat system, sometimes called a “dual-fuel system” in Wikipedia: “a hybrid heat system reacts to changing temperatures and automatically adjusts to the most efficient energy saving method available to heat or cool a home. It can be a fuel-saving alternative to traditional heating and cooling systems in that it combines a furnace with a heat pump, rather than an air conditioner.”

Other than Quebec, where electricity prices remain lower than elsewhere in Canada, that “most efficient energy saving method” is anything other than straight resistance electric heat. As long as I can remember, our industry demonized electric heat and for good reason: heating with electricity is only for the rich and famous.

Pressured by governments, environmentalists and consumers groups, the automotive industry is moving rapidly into electric powered cars, either hybrid or full battery electric. Still a tiny fraction of the car market, it is curious that a potential electric car buyer would likely recoil at the thought of buying an all-electric heating system.

As I have noted in previous articles, electric baseboard heaters make a homebuilder’s life much easier: it is inexpensive; there is no need for a chimney or vent and no condensate to drain; and no CO is produced. At point of use they are 100 per cent efficient; offer quiet operation; are reliable and require little maintenance; and are installed by licensed electricians. No need for the HVAC trade–yikes, that is us!

Related: New heat pump technology remedies past issues

Obviously, the benefits of a forced warm air heating system far outweigh the simple convenience of baseboards; namely, humidification and dehumidification combined with air cleaning all in one package.

The point of a hybrid system is to reduce operating costs while maintaining year-round comfort conditions. In most cases, a hybrid system consists of an outdoor air source heat pump connected to an indoor coil or air handler. The indoor unit could be a gas furnace, oil furnace, electric furnace or an air handler. When mounted downstream of a fossil fueled or electric furnace the indoor coil is known as an add-on hybrid system.

An outdoor heat pump, connected to an air handler containing electric strip heaters downstream of the indoor coil, is known as an all-electric hybrid system. Typically, the indoor appliance is sized to carry 100 per cent of the heating load in case the outdoor unit suffers a catastrophic failure. The outdoor unit must be a rated AHRI match with the indoor coil, fossil fuel furnace or electric heat air handler.

Hybrid heat systems continue to evolve. For example, the Unico System small duct high velocity heat pumps feature inverter drive outdoor units connected to specialized air handlers with electric auxiliary heat or even a hot water coil. Geothermal heat pumps with electric heat or fossil fuel backup prove that air-to-air heat pumps are not the only hybrid heat option on the market.

Controls strategy

When combined with a gas or oil furnace, a hybrid heat pump must utilize a dual-fuel compatible add-on control or thermostat. Today’s thermostats, working with an outdoor temperature sensor, “decide” when to shift from heat pump heating to fossil fuel operation. Conventional air source heat pumps suffer from declining heating capacity as the outdoor temperature plummets, thus two modes of operation for add-on hybrid heat systems have traditionally been available.

Non-Restricted Mode: The latest dual fuel thermostats, depending on the manufacturer, may use a load value to determine which unit should operate. Thermostats that monitor proportional error (the set point temperature compared to the actual room temperature) and integral error (the length of time the room temperature has been away from the set point) will thus develop a load value using the formula P + I = LV.

For a single stage unit, a load value of zero means the unit is off, a load value of 100 means the unit is on. A two-stage unit would have a load value range from zero to 200. Thus, a load value of 150 means a request for 100 per cent first stage heat and 50 per cent demand for stage 2 with a multi-stage unit. Thus, the dual fuel control will determine which mode operates based on calculated load value.

When the load value is within the compressor heating range (zero to 200 LV) the two stage heat pump operates. When the load value climbs into auxiliary heat range (beyond 200 LV), the heat pump cycles off and the auxiliary heat takes over. Once the load value drops below auxiliary heat range, the compressor restarts and the auxiliary heat stages off. This mode works well in milder winter climates as there is a built-in delay between modes that may allow room temperature to swing too much in colder climates.

Restricted Mode: This setting is probably the best mode for cold climates. Using an outdoor temperature sensor, the installer sets an outdoor temperature lockout point so that compressor operation is disabled below that point. Only auxiliary heat functions below lockout.

At temperatures above lockout, the system operates like non-restricted mode. Auxiliary heat can also be prevented from operating above an installer selected outdoor air temperature. For example, with an auxiliary heat lockout of 40F, only the compressor will run above that temperature. The restricted mode lockout typically has a 4F dead band meaning that a compressor locked out at 40F would not resume operation until the outdoor temperature rises above 44F. Dual fuel thermostats have an emergency heat function that converts the system to auxiliary heat only operation.

All Electric Systems Using Matched Air Handlers: The heat pump will run at all outdoor temperatures, although some manufacturers may have the outdoor unit shut down around 4F leaving the auxiliary heat to handle all the heating load at exceptionally frigid outdoor temperatures. As the compressor continues to run, the hybrid thermostat signals electric heat strips to cycle on and off as required to satisfy second stage or even third stage.

Balance point

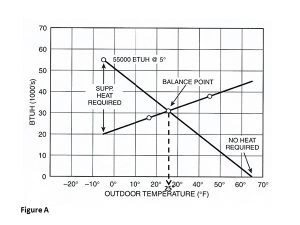

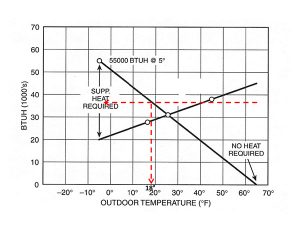

Figure A

An air source hybrid heat pump can help to keep operating costs lower for some, but not all, potential customers. Fluctuating fossil fuel prices combined with government rebate programs, starting with the “off-oil” conversion incentive of the late 1980s, often resulted in hybrid installations that, to put it mildly, disappointed unsuspecting homeowners looking only to save a few heating dollars. Sizing the unit into an appropriate duct system, finding a proper location of the outdoor unit, and understanding how to determine when the heat pump should hand-off the heating job to the backup system continue to be obtuse concepts for many contractors, to say the least.

Balance point is an effective means of determining lockout temperatures in any given application. In order to determine a balance point temperature, the heating professional must perform a shell heat loss calculation and have the manufacturer supplied heating performance data for the AHRI rated hybrid system on-hand to be applied in any particular application.

The first balance point occurs at the outdoor temperature where the heat pump cannot provide 100 per cent of the heating requirement. A gas furnace in restricted mode may take over at balance point, or an all-electric system will turn on maybe 10 Kw of electric heat in combination with the outdoor unit’s heating contribution.

“An air source hybrid heat pump can help to keep operating costs lower for some, but not all, potential customers.”

There may be more than one balance point in the control sequence. For example, in an all-electric hybrid system, a second balance point could occur if the heat pump plus 10Kw still is not enough to maintain comfort conditions as the outdoor temperature drops close to the heating system design temperature. Perhaps another 5 Kw will switch on then to further supplement the heating load.

Balance point examples

In Figure A, a building has a calculated heat loss of 55K Btuh at an outdoor design temperature of 5F and 70F indoors. A line drawn from 55K Btuh to 65F outdoor air temperature (point of no heat required) completes the “building slope.” Based on the cooling load, a three ton heat pump will be used. Its AHRI rated performance at 47F (37,500 Btuh) and 17F (27,800 Btuh) has been plotted and another line drawn through those two points complete the “equipment slope.” The balance point for this system occurs where the two line cross, at 25F.

The heat pump output on a design day is approximately 20K Btuh meaning 35K Btuh of supplemental heat will be required. Since 100 per cent backup may be desirable, a two-stage gas furnace of 75K Btuh or greater could be specified. Thus, using restricted mode controls, the heat pump is going to shut down and hand-off 100 per cent of the heating requirement to the selected supplemental heating unit when the outdoor temperature drops below the charted 25F outdoor temperature value.

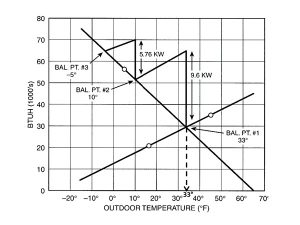

Figure B

Figure B illustrates a hybrid system with somewhat less heating capacity used in the same application as Figure A. The equipment slope is steeper due to decreased performance creating a higher balance point of 33F. At balance point, second stage calls and turns on 9.76 Kw of electric heat with a declining slope that parallels the heat pump only slope. A second balance point is created at 10F, still not enough heat to cover a design day. At 10F, another 5.76 Kw is switched on and the new slope creates another balance point at -5F which should be enough to cover an unexpected cold snap.

Ultimate hybrid heat systems

Declining heat output in Canada’s cold climate has always plagued hybrid heat pumps. Better compressors, improved outdoor and indoor coils, TXV or EEV refrigerant metering, system matching and more sophisticated controls (especially defrost control) have contributed greatly to improving the performance and reliability of hybrids, but the most significant advances have been made only lately.

Ductless hybrid with baseboard supplemental heat. Source: Panasonic

The introduction of cold climate ductless heat pumps using dense vapour injected compressors has changed everything. The best units can maintain 100 per cent heating output down to -4F. Anton Wolmarans, general manager at Multi HVAC Inc., told me about a new cold climate unit: “Applying this product in heating applications where no natural gas is available will provide heating cost savings over straight electrical, or even propane and oil heat.

“The COP of the heat pump will outperform these fuels in most cases, especially in climates that have very few extreme cold degree days and the electric heater will operate infrequently providing high seasonal efficiencies,” said Wolmarans. “The majority of the seasonal heat requirements can be provided with the heat pump, as these models can provide up to 14 HSPF.”

The cold climate unit, in true hybrid fashion, can signal a baseboard heater to operate as needed. Panasonic, Haier, Mitsubishi, Samsung and a host of other manufacturers have cold climate hybrids on the market. Perhaps the baseboard electric heater will ride again.

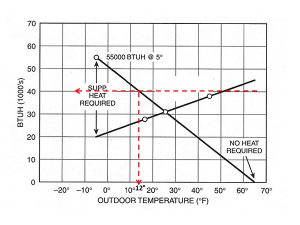

Figure C

Then there are geothermal hybrid systems with an advantage over air source heat pumps because there is nothing outside to worry about. Geothermal heat pumps produce a constant amount of heat at or near full capacity regardless of outdoor temperature. In Figure C, I included a red dotted line based on a three-ton ground loop geo unit with 40F entering water at 8.0 gpm produces about 42,300 Btuh (full load) under those conditions. The balance point drops to 12F, substantially better than a conventional air source heat pump. A three-ton cold climate ductless heat pump with a continuous heat output of 36,000 Btuh (to -4F) would have a balance point of 18F (see Figure D).

Figure D

The market still needs hybrid heat pumps, especially geothermal and cold climate models. In Quebec and Atlantic Canada where ducted systems are rare, a geo or cold climate hybrid will keep the need for electric resistance heating to a minimum.

When better-insulated residential housing becomes the norm, fossil fueled furnaces will not be needed. A small hybrid with maybe a baseboard or two for backup will be the new normal in residential housing. It has been a long time coming.

When does a heat pump require auxiliary heat? See more in HPAC’s February 2018 issue, online now.